Designed for ISO EN17141 and EU GMP Annex 1:2022 Compliance

ActiveCountR

Designed to meet the industry need for continuous trouble-free operation and flexible running parameters, the ActiveCountR is the right choice to meet your viable sampling needs.

The ActiveCountR can be operated via the local start/stop button or remotely via a software interface.

Utilizing either a side mount or bottom mount 316L stainless steel impactor, the ActiveCountR offers superior sampling flexibility to meet all of your viable sampling needs.

The compact size provides true “plug and play” functionality in an easy-to-use package that quickly integrates into the LMS Express real-time monitoring systems from Lighthouse. Whether you are sampling within a cleanroom or inside of a Biosafety Cabinet or Laminar Flow Bench, the ActiveCountR will meet your cGMP compliant monitoring needs.

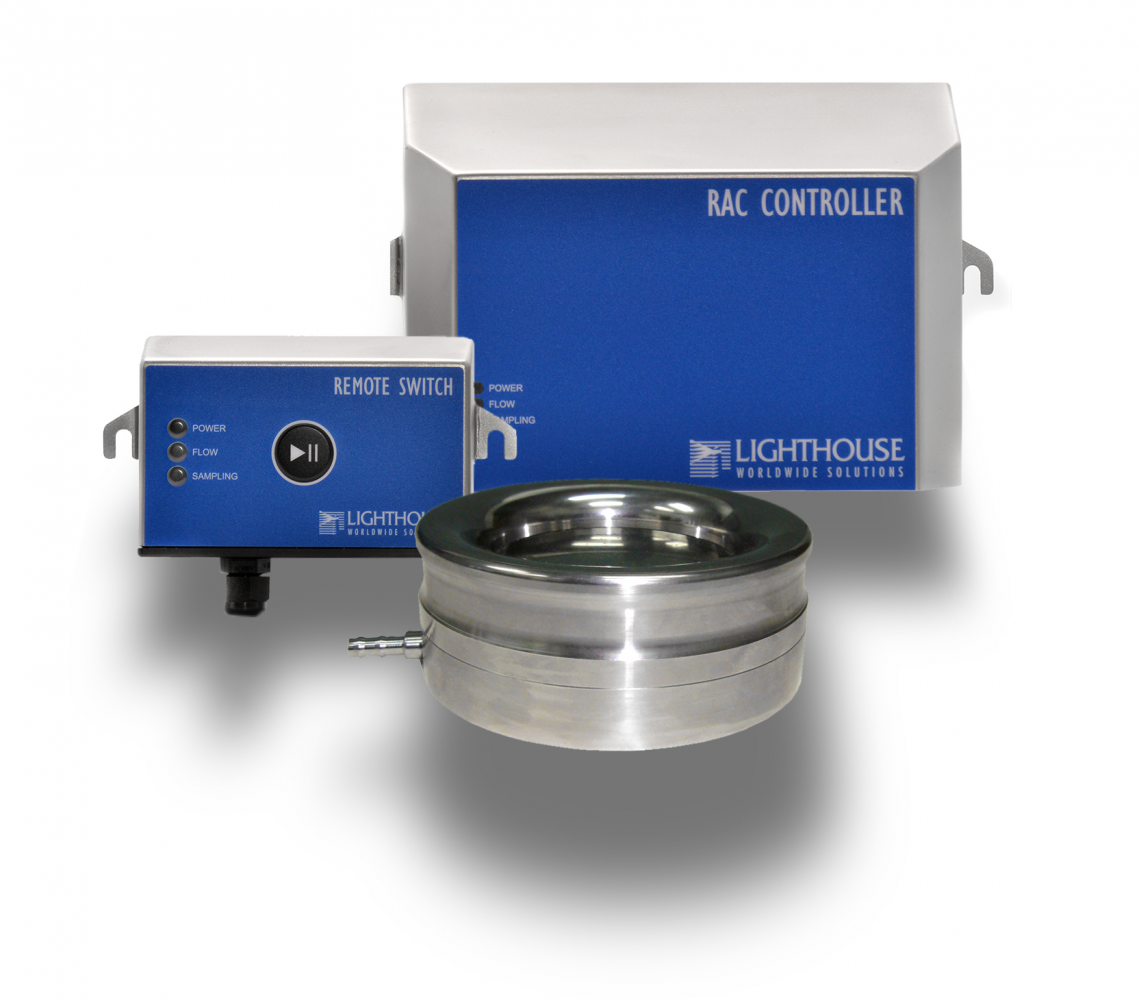

- ActiveCountR

- ActiveCountRp

- Sampling Head

1 CFM Flow Rate

Key Features:

- Designed for EN17141:2020 Compliance

- 1 CFM (28.3 LPM) sample rate

- Utilizes an external vacuum system

- Local start/stop control or remote control via software

- Stainless steel enclosure

- Single start/stop push button

- Local LED status indicators

- Third-party validated sampling head

- 2 year warranty

1 CFM Flow Rate

Key Features:

- Designed for EN17141:2020 Compliance

- 1 CFM (28.3 LPM) sample rate

- Integrated vacuum pump

- HEPA filtered exhaust

- Stainless steel enclosure

- Closed-loop feedback flow control system

- Single start/stop push button

- Local LED status indicators

- Remote or direct mount sampling head options

- Third-party validated sampling head

- 2-year warranty

1 CFM Flow Rate

Key Features:

- Designed for EN17141:2020 Compliance

- 1 CFM (28.3 LPM) sample rate

- 316L Stainless Steel Construction

- Bottom and side mount options

- Third-party validated for impaction efficiency

- Third-party validated sampling head

- 2 Year warranty

Ensuring Purity and Performance: The Critical Role of Particle Contamination Monitoring in Industrial Gases

Discover how our advanced particle counters safeguard the integrity and efficiency of key processes by detecting particle contaminants in essential gases like Argon, Helium, CO2, Ammonia, Nitrogen, and other inert gases. Ensuring the highest standards in industries from pharmaceuticals to semiconductors.